RESEARCH

QUESTION

How can a composite of natural and man-made material increase the durability of

bamboo construction in the modern industrialize construction?

The scientific Vernacular explores the turning points when

inputs of scientific knowledge boost the creative urges of architects for new

forms of architectural expression which were traditionally concentrated in

Vernacular Architecture; taking the leap from a stylist approach to knowledge

based and innovative approach with the use of technological science.

Bamboo has its disadvantages such as decaying, susceptible

to insect and fungal attack. The service life of bamboo is generally considered

as being too short for any worthwhile investment. A problem that compounds the

low natural durability is the hollowness of the bamboo culm, particularly when

compared with the end-to-end massive cross section of wood. If fungi or insects

attack and destroy the outer layer of the bamboo, it may mean the loss of one

quarter of its thickness compared to the total thickness of wood. The

hollowness also offers a relatively safe hiding place for the pests of

destruction. In most tropical countries, the high relative humidity of the air

adds to durability problems. High moisture content in the bamboo also creates

problem in drying process. Besides, bamboo does not contain cross fibers and is

consequently, not designed to bear weight width-wise, with the exception of the

points at the nodes. Bamboo is prone to splitting, especially when standard

construction fasteners, such as bolts, screws and nails are inserted. Special

fastening techniques are required when joining pieces of bamboo.

The diagram below shows the life cycle of an untreated

bamboo:

Since Bamboo itself brings threats towards the mission and

vision of our future development, a combination of kaccha and pukka styles can

be used to increase its characteristic thus improve durability and feasibility

of the various periods stated above. How? What is kaccha and pukka?

Kaccha is a building made of natural materials such as mud,

grass, bamboo, thatch or sticks and is therefore a short-lived structure;

Whereas pukka is a structure made from materials resistant to wear as forms of

stone or brick, clay tiles, metal or other durable materials, such structures

are expensive to construct as the materials are costly and more labour is

required.

To simplify the research question, the research will be researching on the type

of natural and artificial material used to increase the durability of bamboo.

Community in villages know by experience the durability of

the bamboos in their homeseeds. The lower part of the culm is said to be more

durable; and so is the outer part of the culm wall. The starch in the bamboo

attracts fungi and insects, therefore the selection of harvest time during the

dry season will have a better durability. Also, bamboo with flowers is more

resistant to these agents due to its depletion of starch.

The correlation between natural durability is difficult to

establish; most of the facts are based on culture and tradition from the

villages through experience than on physical reality (Kirkpatrick and Simmonds

1958).

There are various durability can be found in bamboo in

terms of its life span and service as a structural member.

Starch makes bamboo

vulnerable to be attacked by fungi and insects. Therefore, reducing start

content of bamboo is the best way to make it less vulnerable. You can reduce

starch content by:

- keeping the culm in a vertical position under a shade for a week after

harvesting

- harvesting only the mature bamboos

- harvesting in winter season

- by soaking the bamboo for 3 to 6 weeks in running water or permanent water

sources

The

durability of bamboo is directly related to how well it is treated at all

stages of its use, including how it is grown, harvested, dried, stored,

transported and installed.

Bamboo fails most

commonly through rot from excessive water contact, and attack from pests

seeking out the sugars in the starch of the bamboo, hence most pest infestation

occurs at the joints and through cracks and holes. Therefore, prevent direct

moisture contact and reducing cracking through careful handling will greatly

increase life expectancy as will surface treatments such as paint and oils.

Harvesting

When harvesting, cut the bamboo neatly and evenly immediately above a

node that is one or two nodes above the ground, to reduce the potential for

fungus to infest and degrade the plant. Using the basic principles stated above

to increase the durability of bamboo.

Leaching

In many cultures freshly cut bamboo is soaked in rivers or streams to

leach out sugars and saps to reduce pest infestation. Leaching is more

effective on smaller sections of bamboo; therefore it should be done after

cutting to length or split while vascular cells are still open. Knocking a hold

through the centre of each node along the length of bamboo will allows saps to

wash away more rapidly.

Bamboo will achieve it is the greatest strength if it is being dried

slowly, uniformly; prior to use and to prevent cracking. The curing process is

being done in a cool, shaded, ventilated and organic material free area. The

culms should be stored horizontally; rotating regularly to avoid splitting from

uneven drying. In the process of drying, the bamboo will loses its leaves and

start turning brown; going through the process of losing starch content and moisture.

On the other hand, storing in a silo as another alternative for its drying

place where shades and ventilation are present. Also, split, woven bamboo is

another strategy for drying to take place quickly.

Kiln

Drying

Using

the present level of drying technology, it is not feasible to dry bamboo poles

due to its incidence of cracking and collapse. However split bamboos are

preferred instead.

Air

Drying

Air drying takes up 6-12 weeks depending on the moisture content and the wall thickness.

Mature culms are preferable; thus it

will not pose any problems of splitting under the sun.

Smoking

(Baking over Open Fire)

The bamboo is stored above the fireplace for few days after applying oil on the

surface; until the colour turns into slightly black. This causes rapid drying

of outer shell and decomposition of starch. However, excessive heat might

develop fissure or crack in fresh bamboo when you apply heat to the freshly cut

bamboo; therefore using a gentle fire and rotating the surfaces constantly is

recommended.

Transport

and Storage

Bamboo culms should be loaded and unloaded by hands; not thrown from the

truck. They should be stored carefully so that air can circulate around each

culm and being protected from ground water and rain; keeping it away from

direct contact with soil due to its route for pests and moisture retention in

it.

Surface treatments such

as application of sumps oil, paint, varnish or other chemicals being applied in

a diluted form to allow deep penetration although surface treatment are not as

effective as penetrative treatments thus require regular top up treatments..

Focus should be given to joints, ends, cracks and nodes as the area has the

most pest infestation. Starch coatings within the culm have to be removed by

boiling or abrading with wet sand if a burning process is required. The

Japanese have refined an artificial method of obtaining a similar colouring

using sulphuric acid mixed with mud.

Treatment of Fresh

Bamboo

Freshly cut culms being

placed upright in containers of concentrated solutions of water-borne

preservatives (5-10%). The treatment takes between 7 and 14 days, losing the

preservative solution in the container and made up to maintain the initial

level of solution.

Sap Displacement

Bamboo culms are

prepared to size and submerged in Borax/Boric Acid solution which is a water

soluble preservative for several days. Preservative rises by wick action as the

sap is sucked up. The preservative enters the culm through ends and holes

drilled in internodes. The soaking process is long enough for the chemical to

soak through the entire structure of the culm.

Modified

Boucherie Process

The Boucherie method was pioneered by Dr Walter Liese of Hamburg University. Borax

is water soluble; it will leach out with continued exposure to rain, losing its

effectiveness. In this method, the preservative is passed under pressure

through the culm till it comes out at the other end of the culm. This can be

applied only to fresh bamboo within 24 hours after the harvest.

Dip

Diffusion Process

Fresh culm with high moisture content (above 50%) are kept submerged in

solution for a diffusion period of 10 to 20 days. This method can be applied

only to split and swan bamboo strips since the moisture causes difficulties for

the penetration to occur. Steaming and quenching, followed by diffusion under

drying conditions is another variation of diffusion process.

Treatment

of Dry Bamboo

Soaking

Air

dried bamboos have only to be submerged in the preservative solution (oil or solvent

type) for a period. The penetration is predominantly by capillarity. If

water-borne preservatives are used, the process is called ‘steeping’. But the

soaking treatment with organic solvent (such as pentachlorophenol, copper,

abietates) works better than steeping in water-soluble preservatives.

Hot

and Cold Method

The bamboo to be treated is submerged in a tank of preservative that is

directly heated by fire after being maintained at a constant temperature for a

period, the tank is allowed to cool. During the cooling process, the

preservative is drawn into the bamboo. The hot and cold method can be used for

green or dry bamboo culms with either Boron or Creosote.

Pressure Treatment

Round and half split

bamboos of thick walled species can be treated with creosote (fuel oil) under

hydraulic pressure. The problem of under pressure can be resolved by drilling

holes or notches between, but this leads to spillage. Therefore, a

vacuum/pressure schedule helps to ensure more inform penetration.

Protection by Design

The design of bamboo is to ensure its good nodal placement and protecting the

bamboo from weather and pests.

Large roof overhangs

prevent direct wetting of bamboo walls in heavy rains; thus using drainage

channels or gutters to discharge water from the building at a certain safe distance.

Bamboo flooring can be protected through building on a slightly sloping site

and using raised masonry or concrete footings. This can be applied on bamboo

columns and wall panels to reduce the risk of termite infestation through the

direct contact towards the ground surface.

Bamboo has got a round profile

therefore creating connections will be leading to difficult geometric

structures at the knot. Various connections can be used; for example, friction

tight rope connections, nuts and bolts connection, positive connections,

interlocking connections. Besides that, bamboo is hollow in the middle of the

cane; therefore it can be reinforced by pouring concrete inside.

Traditional Methods

Joint Bracing

While bamboo has been used for centuries, the traditional methods

of lashing bamboo together are not appropriate for the design of long span

trusses. These lashed connections also do not fully utilize its strength; it

solely rely on friction, transferring load between members is limited thus

require more members to do the same job. Therefore joints in bamboo always have

been difficult because it is hollow, has nodes and resists only a little shear

stress. Many traditional joints suffer from weakness or deformation. Many

joints cannot take advantage of the strength of the culm itself and a special

problem is to design a joint for tensile forces.

Modern Methods

Bolting Joints

Modern connections have been proposed by Huybers, Shoei Yoh and Renzo

Piano. These connections solve the issues of complex geometries by joining the

members in various ways. These connections require puncture of the bamboo walls

sine all fibres in a bamboo culm run parallel once a bolt is placed through it

and the connection loaded in tension, the bolt acts like a wedge and splits the

bamboo. Also the puncture allows moisture to enter the culm and accelerate

decay.

Nodal Placement

With an understanding of the bolt alone concentrate much on the

wall of the bamboo, the void between the solid internal nodes is filled with

solidifying mortar where every bolt penetrates each of the bamboo culm. Members

of a truss come together at angles and tension forces are anticipated, a steel

strap is placed to bridge the pieces. It is important to design with redundant

system that is capable of both compression and tension. This frame truss system is certainly preventing bamboo from bending

and buckling in the middle of the culm. Larger

holes were drilled into the bamboo to insert the mortar into the joint

segments. The mortar was mixed with the optimal quantity of water; the bamboo

pieces where then duck taped together to maintain their positions as they were

filled with mortar and left to cure for a week. Once mortar is cured, the tape

can be removed.

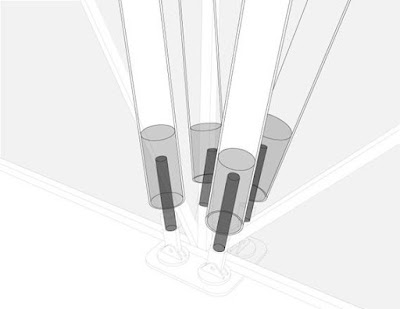

Bamboo +

Mortar + Rebar

Though holes were drilled into bamboo segment to insert re-bars. This re-bars will absorb most of the stress moments and allow the bamboo structure to sustain high stress impacts as occur during earthquakes. Bamboo tends to shrink with time making the string joinery slack and insecure. Therefore the joinery system relies on bolts and mortar-fillings maintaining their shape over time. Bamboo filled with mortar are reinforced by an additional the rebar is embedded in mortar, the load is transferred evenly

across the member's cross section and can transfer high axial loads to the bamboo.

Bamboo + Mortar + Rebar + Clamp

The bamboo is cut at the end axially crosswise to generate a cone by tightening a steel clamp. The cone is filled up with mortar so that the cone is able to transfer its force to the outer high tensile fibres. A common steel clamp is also placed at the end of the member to provide confinement of the bamboo and prevent splitting of the bamboo. Because the rebar is embedded in mortar, the load is transferred evenly across the member's cross section and can transfer high axial loads to the bamboo. Finally, the incorporation of the steel gusset plate makes the bamboo easy to connect in any configuration desired.

New Joints

In order to allow bamboo for spatial and light structures, it is important to have a durable joint which does not bring much weight to the structure and which works under high forces to take advantage of the high resistance of bamboo fibers. The alternative joints for bamboo and by some techniques which are already used in steel constructions. The joint is light, strong and appropriate for easy assemble and disassemble.

Based on the various methods to increase the durability of

the bamboo from its own solid wall towards its connectivity on the building

structure, bamboo can almost become a universal element. This research has

provided a proof of concept for the durability of bamboo itself can be developed

by using the natural methods and artificial methods; thus increasing it

durability on structure by roughening the inner surface of the bamboo member,

filling a portion with mortar, embedding re-bar and welding several of these

members to gusset plate. Having both of these characteristics can then be used

to construct and span moderate distances, thus providing a safe and predictable

behavior. This research will help facilitate the future use of bamboo in a cost

effective solution to many parts of the world.